Sinter Batching System

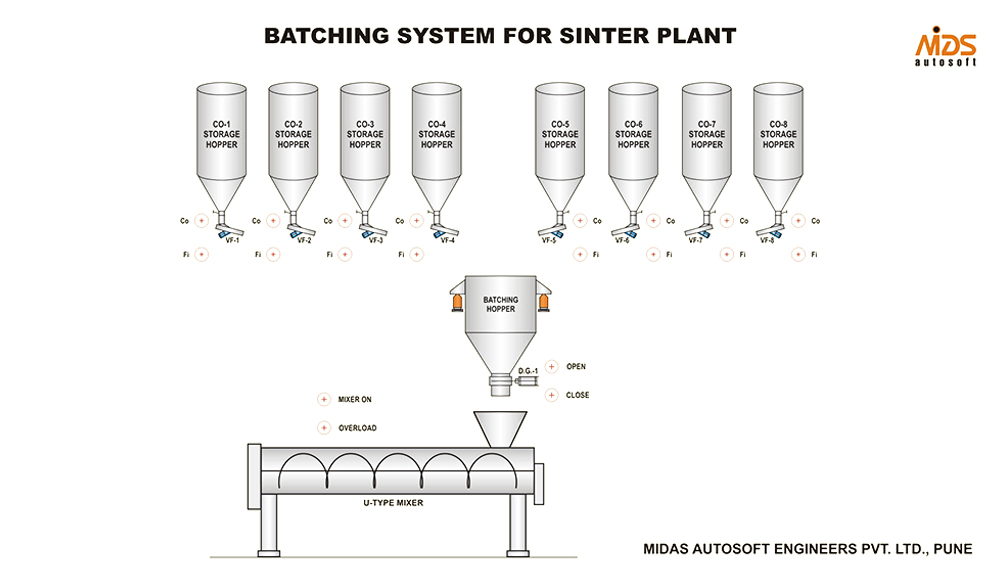

System Description: Batching hopper is provided below storage hoppers (i.e. 4/6/8 Nos.). Batch hopper is installed on imported Load cells. The Vibro-feeders are provided in between storage hoppers and Batch Hoppers for charging the raw material in to Batching hopper. Batch hoppers have pneumatic cylinder operated gate to discharge the batched materials in to the mixer. Load cells are connected to Batch controller / Weighing indicators, which are mounted in Batching system panel for weight indication and batching operations. The Batch controllers are having facility to program for individual set points and manual component, inputs such as Start, Stop and Abort the batch, outputs for vibro feeder, gate, timer and discharge sequence.

Batch house panel will have switches, lamps, timers, power supply, relays, VFD’s for conveyer/screw feeder, etc. for Automatic/Manual operation and Mimic diagram of the complete Batching system to know the status (ON/OFF, Coarse/Fine, Overload, etc.) of the field Instruments like Screw feeder, Conveyers, Gate/Ball Valves, Mixer and Mixer gate.

In Auto Mode, system will operate in single batch or multiple batches by pressing singe start button.

As the batch starts, the vibro- feeders will start the sequence as per programming and will stop as per set point. On completion of all the material charging the discharge gate will open automatically. The discharge gate will close after material value in batch hopper reaches near to zero during discharge process. The next batch will automatically start as per batch mode select.

In Manual Mode, switches are provided for vibro feeder, discharge gate & mixer. Operator can take the batch with help of the weight displayed on Batch controller 7 Segment LED display and switches.